Battery Replacement

The traction battery of our Prius needs to be replaced. The main problem with the original battery is that there is no Battery Management System. There is only a battery monitoring function in the battery ECU. Furthermore, the energy density and cost of replacing the old battery make a lithium ion solution more desireable. It would also be nice to replace the battery ECU with a custom solution that can be scaled for larger capacity batteries.

Initially we will repair the current battery with new modules and replace the battery ECU with our own custom one. Then we can use electric vehicle cells to replace the NiMH with Li-ion.

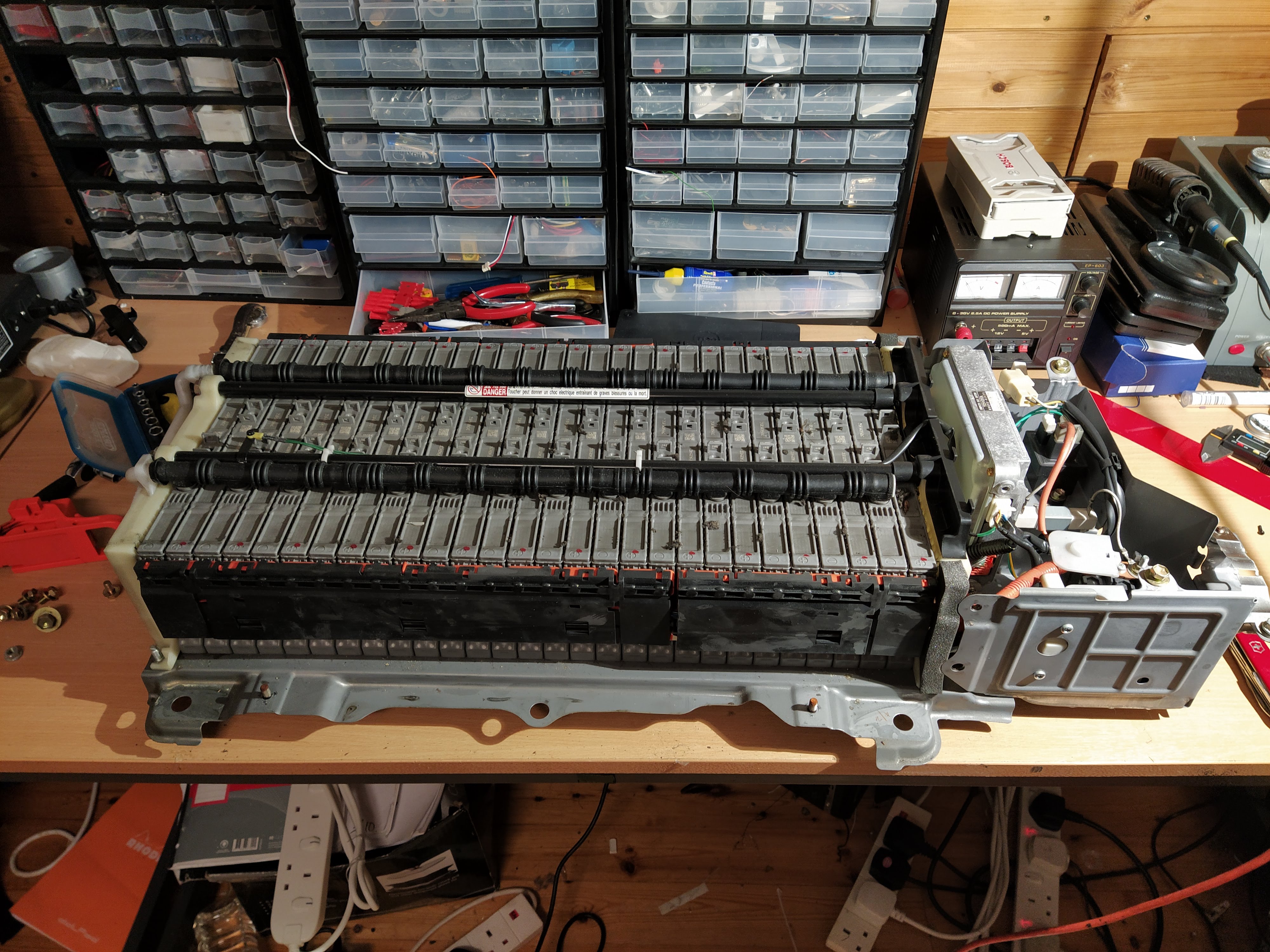

Original battery 🔋

The high voltage battery (also known as the traction battery) is a 201.6V NiMH battery composed of 28 modules (7.2V each), where each module is made of six individual 1.2-volt, 6.5 Ah Panasonic Prismatic NiMH cells. The 28 modules are connected in series to produce a total energy storage capacity of 1.310kWh (201.6-volts × 6.5 Ah).

Total voltage: 201.6V

Total energy storage: 1.31kWh

Current output: 186A

Number modules: 28

Module voltage: 7.2V

Module energy: 46.8Wh

Module weight: 1030g

Module energy density: 45.44Wh/kg

Number cells per module: 6

Cell voltage: 1.2V

Cell energy: 7.8Wh

Battery modules: https://www.peve.jp/en/product/np2/ Breakdown of prius system: https://ur.booksc.eu/book/72082550/3d5351

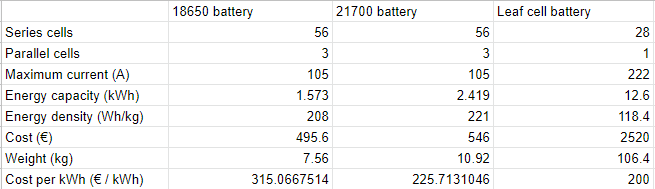

Results of analysis 🧪

I looked into building a custom battery using three different types of cells 1) 18650s, 2) 21700s and 3) Nissan leaf pouch cells. Before I did this analysis, I wanted to build a custom battery from cylindrical cells, but we decided to repair the current battery and wait for when we transfer a second hand EV into the car. The main reasons for this are cost and manufacturing:

- Cost: The larger each subunit is, the better bang for your buck you get. For example, the nissan leaf cost per kWh is 37% cheaper than 18650s per kilowatt hour.

- Manufacturing: The nissan leaf cells can be bolted together and each cell contains more energy, so it much easier to build a large battery.

- Link for the 18650 cells used: (US18650VTC5A 2600mAh - 35A) https://eu.nkon.nl/sony-us18650vtc5a-flat-top-reclaimed.html

- Link for the 21700 cells used: (Samsung INR21700-40T 4000mAh - 35A) https://eu.nkon.nl/rechargeable/li-ion/21700-20700-size/samsung-inr21700-40t-4000mah-35a-clear-wrap-reclaimed.html

- Link for the Nissan Leaf cells used: (A123 pouch cells) https://www.greentecauto.com/hybrid-battery/repurposed-batteries/nissan-leaf/nissan-leaf-battery-module

Lithium Ion replacement

Specification:

- Module voltage of 14.4V roughly

- At least 1.31kWh of capacity

- Power output of at least 20kW

- 20kW @ 201.6V = 100A of current continuous

Warning: Detailed nerd stuff and rough work below ⚠️

Design Procedure:

- Calculate number of series cells from nominal voltage (this will always be the same)

- Calculate range of parallel cells from capacity

- Calculate range of maximum current per cell

- Battery energy capacity

- Battery energy density

- Battery cell cost

Good cell brands:

- LG

- Panasonic

- Samsung

- Sanyo

- Sony

- Murata

18650

Cell voltage: 3.6V

Cell capacity: 2Ah to 3.5Ah

Cell weight: 45g

1. number series cells = 201.6V / 3.6V = 56

2. total capacity/(cell capacity × cell voltage × number series cells)

1.3kWh/(2Ah × 3.6V × 56) = 3.22 = 4

1.3kWh/(2Ah × 3.6V × 56) = 1.84 = 2

2 > number parallel cells > 4

3. max current / number parallel cells

100A / 4 = 25A

100A / 2 = 50A

25A > cell current > 50A

The final battery would be 56s 201.6V 3p (3Ah cells with 30A max current).

4. energy capacity = 2.6Ah × 3 × 201.6V = 1.573kWh

5. number of cells = 56 × 3 = 168

weight = 168 × 45g = 7.56kg

energy density = 1.573kWh / 7.56kg = 208Wh/kg

6. cost = 168 × €2.95 = €495.6

US18650VTC5A 2600mAh - 35A : https://eu.nkon.nl/sony-us18650vtc5a-flat-top-reclaimed.html

21700

Cell voltage: 3.6V

Cell capacity: 3Ah to 4.9Ah

Cell weight: 65g

1. number series cells = 201.6V / 3.6V = 56

2. total capacity/(cell capacity × cell voltage × number series cells)

1.3kWh/(3Ah × 3.6V × 56) = 2.149 = 2

1.3kWh/(4.9Ah × 3.6V × 56) = 1.32 = 2

number parallel cells = 2

3. max current / number parallel cells

100A / 2 = 50A

cell current = 50A

The final battery would be 56s 201.6V 3p (4Ah cells with 35A max current).

4. energy capacity = 4Ah × 3 × 201.6V = 2.419kWh

5. number of cells = 56 × 3 = 168

weight = 168 × 65g = 10.920kg

energy density = 2.419kWh / 10.920kg = 221Wh/kg

6. cost = 168 × €3.25 = €546

Samsung INR21700-40T 4000mAh - 35A : https://eu.nkon.nl/rechargeable/li-ion/21700-20700-size/samsung-inr21700-40t-4000mah-35a-clear-wrap-reclaimed.html

Nissan leaf cells

1st Generation had 4 cells per modules. Each cell is 3.75 volts nominal with two pairs of parallel cells inside each module. This gives a module voltage of 7.5V. The cells are a pouch style. Hypothetically, it would be possible to rewire wire the bus bars inside each module to give 15V per module with a smaller maximum current. However, this would be difficult to do and honestly not worth it. The goal is to make the battery easy to make and repair.

Nissan leaf battery have no active cooling system also, which severely reduces their lifetime. The battery is literally a sealed container that relies on conduction to remove heat. Therefore each of the modules are pretty poor at removing heat and a new cooling system would have to be designed.

Module voltage: 7.5V

Module energy: 500Wh

Module weight: 3.8kg

Cell voltage: 3.75V

Cell energy: 125Wh

Cell amp-hour: 30Ah

Number of modules: 48

Battery voltage: 360V

Battery energy: 24kWh

Motor power: 80kW

Battery max current: 222A

Module price: €90

1. number series cells = 201.6V / 7.5V = 28

2. total capacity/(cell capacity × cell voltage × number series cells)

1.3kWh/(3Ah × 3.6V × 56) = 2.149 = 0.3714

number parallel cells = 1

3. cell current = 222A

The final battery would be 28s 210V 1p (60Ah cells with 222A max current).

4. energy capacity = 60Ah × 1 × 210V = 12.6kWh

5. weight = 28 × 3.8kg = 106.4kg

energy density = 12.6kWh / 106.4kg = 118.4Wh/kg

6. cost = 28 × €90 = €2520

A123 pouch cells: https://www.greentecauto.com/hybrid-battery/repurposed-batteries/nissan-leaf/nissan-leaf-battery-module

Other EV battery technologies

Shape

Cylindrical: Tesla are by themselves here

Pouch: Nissan Leaf and Chevy Volt

Prismatic: German companies like BMW i3 and Porsche Taycan

Cooling

There are only really two cooling options: Air cooling and liquid cooling. Most EVs use liquid cooling like Tesla, BMW, Porsche and Chevy. Tesla uses a metal pipe that is wound around the cells. The Chevy volt uses coolant plates in between each cell. Most other manufacturers put their batteries on a cold plate.

Of course there is a third option which the Nissan leaf has taken; No cooling! 🙄 Stay well clear of those cars!!!

Tesla Model S

Tesla (https://www.quora.com/What-is-the-C-rating-of-Teslas-18650-batteries - Karl Young’s answer):

- NCA (LiNiCoAlO2) has specific=energy of 250Wh/kg

- 3.1Ah @ 3.6V

- 1C for max life

- roughly 5C on ludicrous mode