Hub Motor Shopping

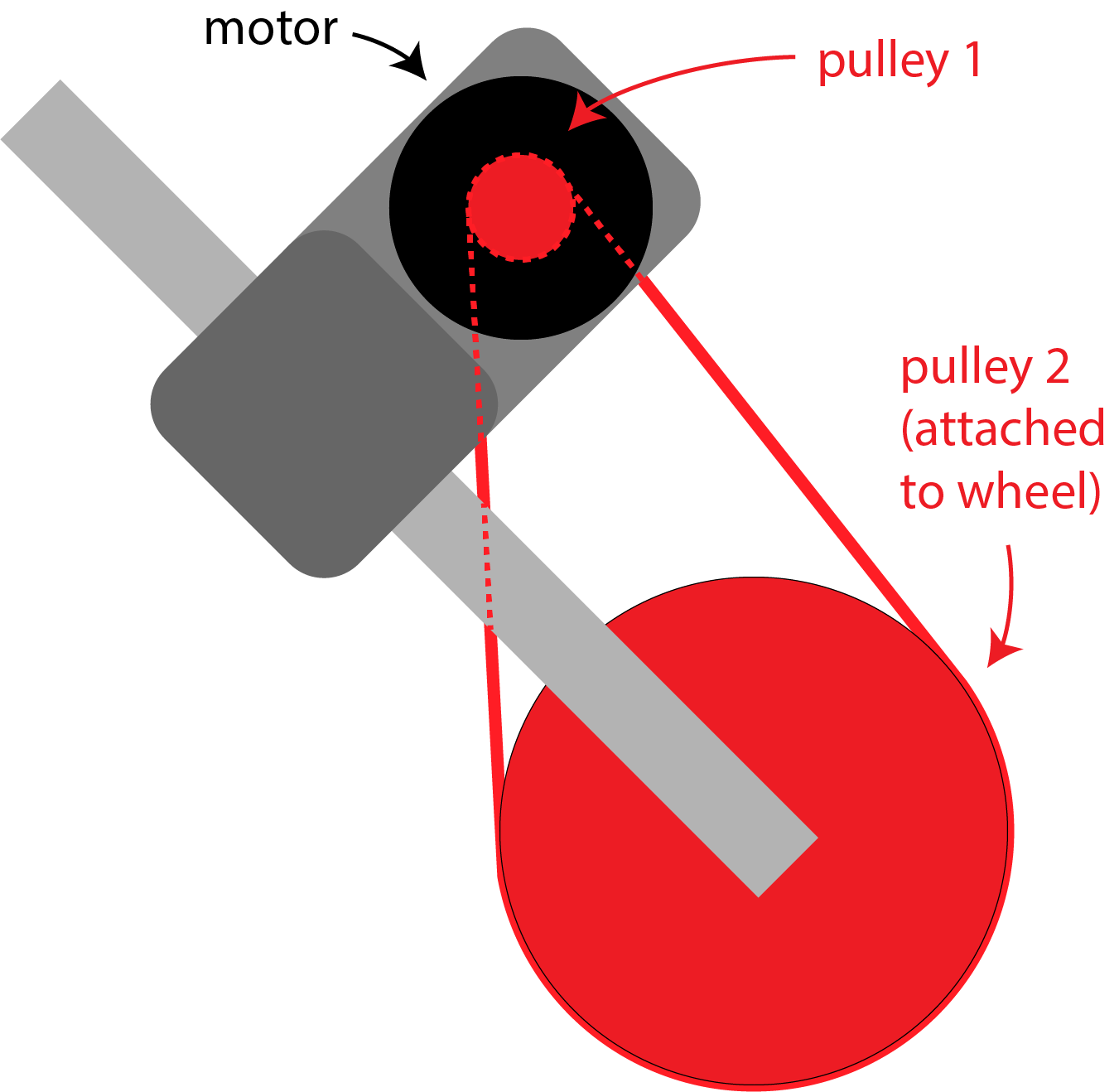

The last drive train that I had consisted of a Remote Control (RC) plane Brushless DC (BLDC) motor, two pulleys and a timing belt. The BLDC motor is electronically commutated and needs a controller to create the the correct signals. The strange thing about BLDC motors is that they are actually AC motors not DC motors 😆

Problems with the old system

Although my old electric bike suited my needs quite well and it was perfectly functional, there were some issues that it had.

- The belt would slip if the wheel was put under too much load.

- The mounting system to the wheel had to be tightened and adjusted periodically.

- The belt had to be replaced every 6 months or so due to wear.

- The motor was precariously mounted less than a centimetre from the spokes (which is what led to its demise)

To sum up, the pulley system’s downfall was that everything could become loose and it’s power was limited by this. There is always usually around 5% loss in power if not more from these drivetrains.

Other options

I have decided that I was going to splash the cash and buy a premade motor assembly specifically for eBikes. The most expensive part of the bike is usually the battery anyways, and I saved a lot of money by building it myself. (PS. I actually tried to skimp on the motor too 🙄 )

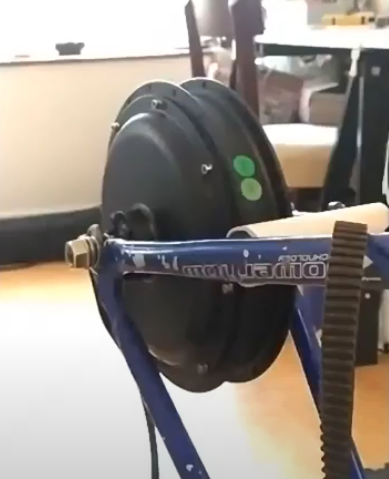

1. Hub motor

Hub motors are very cool because they have no drivetrain per se. They’re literally a big BLDC right actually the wheel hub. This makes these motors very reliable and very very easy to fit onto a bike. Both the front and the rear wheel can be fitted with a hub motor.

They do have their issues however. BLDC motors run most efficiently at high speeds, which hub motors aren’t usually subjected to. Some hub motors have built in gearboxes, but that comes at a price. Furthermore, they are very heavy and since the entire motor is turning, it adds a lot of momentum to the wheel when accelerating and decelerating.

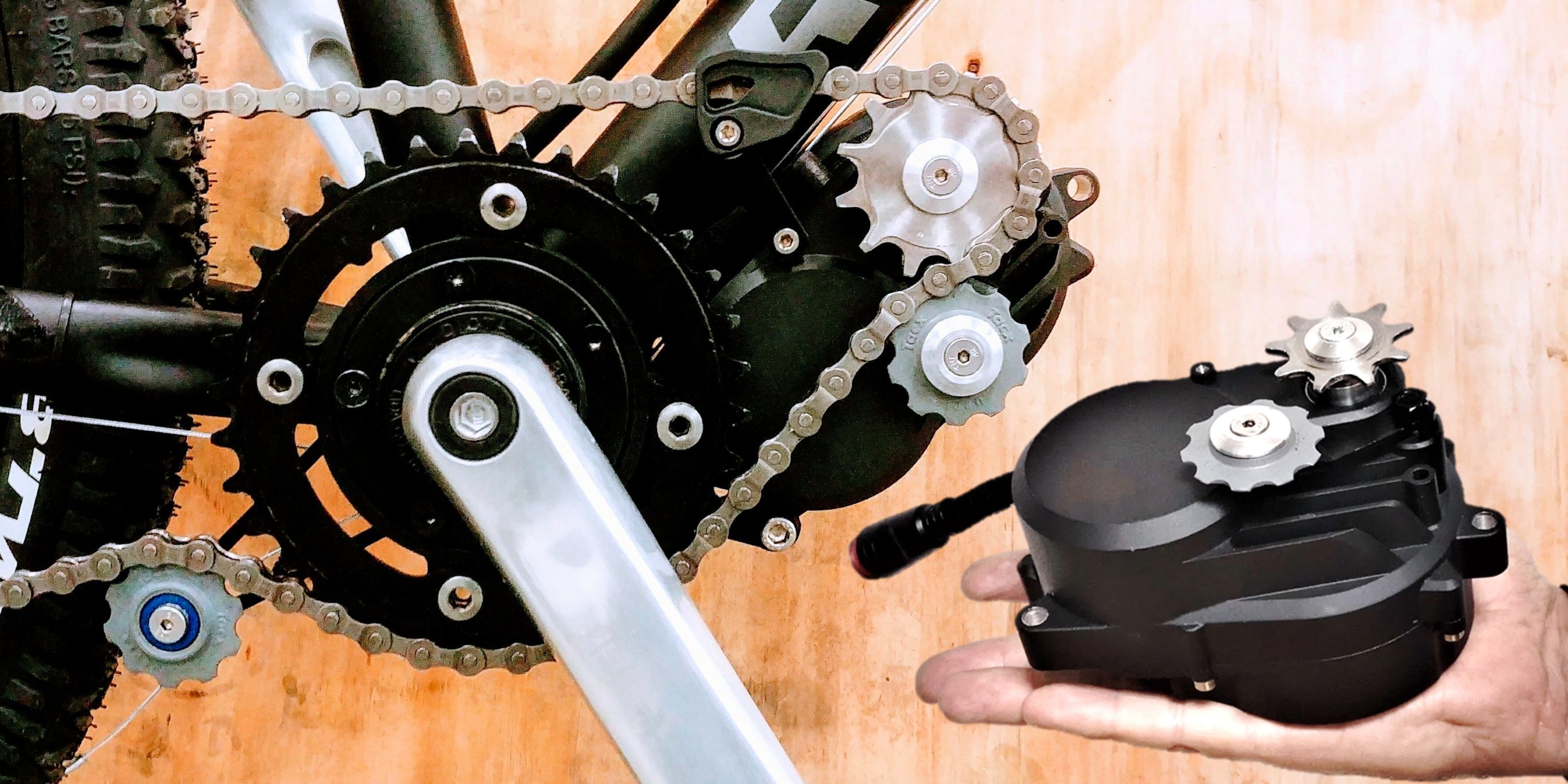

2. Mid drive

Mid drive motors attach at the pedals and interface between the pedals and the wheel. They do not add much momentum to the system and can monitor the pedals much more easily. They also might have a lower profile.

Mid drive motors contain extra drivetrain elements and are more difficult to fit than hub motors however.

Final decision

I decided to get a hub motor 😁 I wanted to get a hub motor for a number of reasons, but they boiled down to price, drivetrain simplicity and fitting. At the end of the day, I want to buy something that would also be difficult for me to make myself, because otherwise I would feel like I could have made it myself for cheaper. That’s the reasoning of a student engineer for you I guess.

The hub motor I got was a 1500 watt rated 48V hub motor from aliexpress and it cost me €137.28 including shipping and it came on 11th September. This link might be broken: https://www.aliexpress.com/item/32988879954.html.

This is my reasoning for buying this specific motor:

- Price - For a hub motor of the same power the going price was >€200.

- Hub motor only - I only wanted the hub motor. This is because I could reuse spokes from two old wheels I had and get a cheaper motor overall.

- Trustworthy - At €137.28 for the motor including shipping, it seemed like a reasonable price. Many motors I saw were much cheaper, but could have easily been lower power. This motor that I got had advertised very clearly what it was and reviews backed this up.

And here she is in all her glory. I literally hooked it up as soon as I got it and it worked right off the bat. Now I just have to build the wheel and do the rest of the upgrade 😬😅