Starting the Audi TT after a year

Preparations

Provided thatn an engine is healthy, it only requires air, fuel and spark to run. To this effect, to get my engine running well again, I overhauled each of these systems to give the engine the best of what it needs:

- Air

As you may know from previous updates, the old turbo was leaking oil in the seals causing oil to mix with the air. I replaced the turbo with a new unit as I discovered it couldn’t be replaced because of a very large crack in the turbo body.

I also fitted a new OEM air filter (no crappy cone filters here) which was a significantly easier job than the turbo replacement and thankfully doesn’t require the engine to be removed :)

- Fuel

This was in reasonable working order. I did a flush of the system before I began the overhaul and took out the fuel sender previously.

However, the fuel in the tank was quite old so it would probably not run as well as it should until new fuel is added to the tank.

- Spark

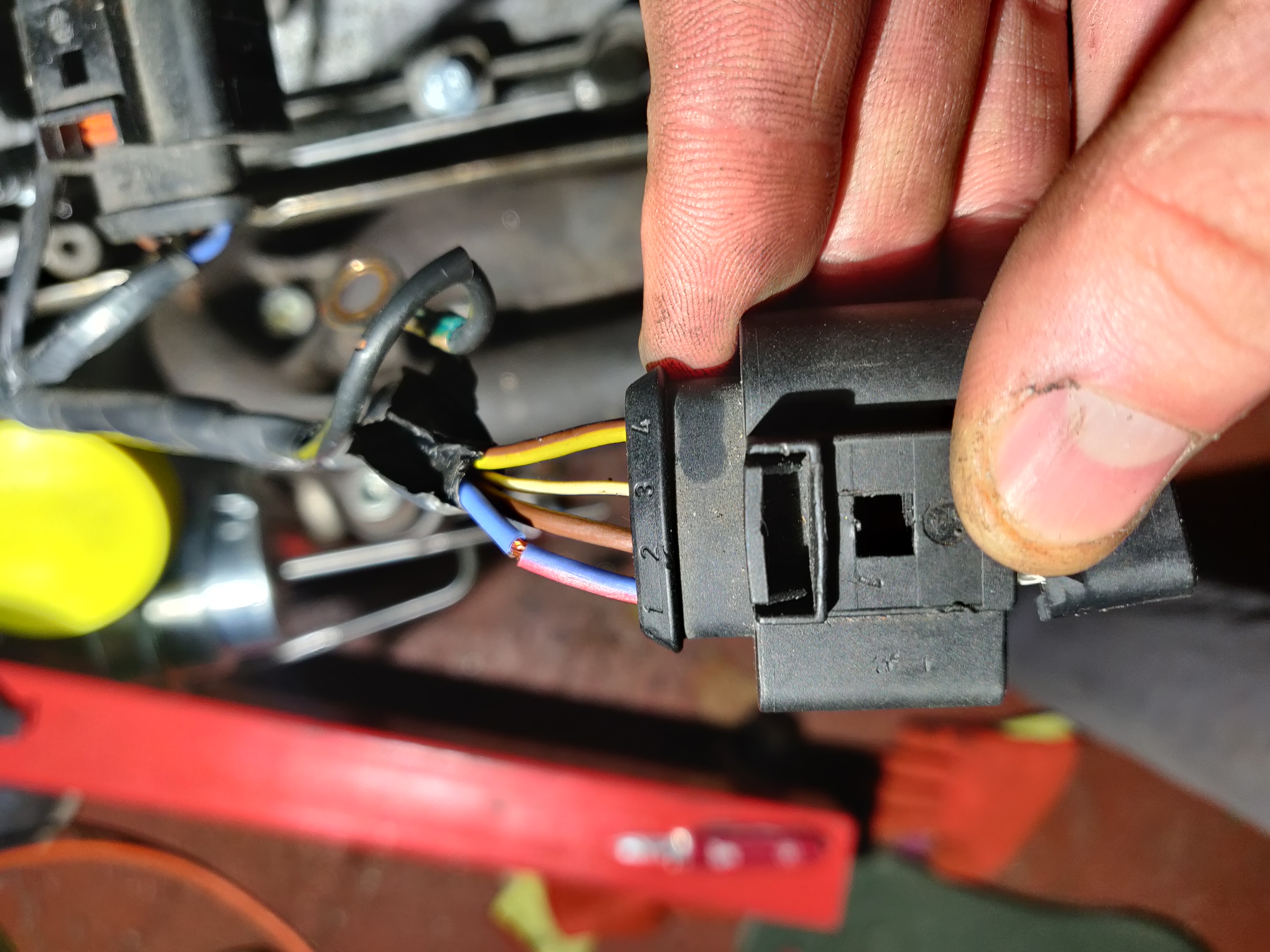

The ignition wiring loom to the coilpacks was in poor condition. It seems that some mechanics in the past spliced into the ignition wires for diagnosis. This resulted in a lot of splits in the wiring. I made repairs to the loom to insulate the exposed wires. Half of the coilpack connector tabs had also broken due to some hamfisted attempts at removing them in the past. I replaced each of the connectors.

I also replaced the spark plugs with new OEM Bosch plugs pre-gapped to the recommended 0.7mm.

First Start

I connected the battery and sure enough it started right up. It didn’t even require many turns of the starter, just enough to get the fuel pressurised. I couldn’t believe my luck!

Not without its faults

While it started up beautifully and I could not have asked for a better result, not everything was rosy.

- There was quite a significant power steering leak due to a loose banjo bolt on the new power steering rack. A relatively easy fix of tightening the banjo bolt did the trick.

- There was also a minor coolant leak from the banjo bolt to the cylinder head. Again a quick tighten solved that issue. Thankfully the leaking banjo bolts were easily accessible and not buried like the the banjo bolts on the turbo, that would’ve been a much more awkward fix.

- After running the engine for a couple of minutes a significant quantity of smoke began to eminate from the exhaust manifold/turbo area of the engine. This was a bit startling but I soon realised it was because I sprayed an entire bottle of WD-40 on the exhaust manifold to clean off swarf. Crisis averted :)

- I had foolishly forgotten to close the coolant flush quick-release valve and when the engine got up to temperature it dumped the coolant on the ground. Again an easy fix and a lesson learned.

- When I started it I noticed an occassional misfire every 40 seconds or so. If it crops up again, I will investigate it more but I put it down to a combination of old fuel and that I (in my more naive days) accidentally connected the Evap system for reusing fuel tank vapours the wrong way around.

First Drive

The next order of business was to get all of the new fluids in the car bled. If you want to find out how to bleed all of the fluids on your VW group 1.8 engine then this post is for you.

Once that was sorted, all of the necessary suspension components were torqued to spec (I would definitely recommend getting a Haynes manual to torque suspension components, there’s a reason there is a torque spec after all), wheels were fitted and the car was placed back on the ground.

The first drive was a great success. Other than the tracking of the front suspension being miles off, it drove perfectly. The new turbo is making a very healthy quantity of boost as the marks on our chipped driveway show. I connected an OBD-II reader to observe the boost pressure, engine temperature and fault codes. All looks very healthy except for a lambda sensor fault code because there’s only one lambda sensor fitted to the car. I may either make up a circuit to spoof the lambda sensor or just clear the code for the NCT.

The Exhaust

I was expecting trouble with my 3 inch €150 downpipe and decat pipe from Ebay. There was very little clearance in the exhaust tunnel when I fitted it. However, it seems to be working very well with no rubbing to report of and no exhaust blow.

I was a bit worried that it would make the car much louder than the stock exhaust (I don’t like loud cars :) but it really hasn’t. It just makes for a little bit more of a low-end rumble on idle and a clearer sound when revved. Great success in my book.

Other problems

The only other thing I have noticed is that the cooling fan doesn’t seem to be coming on when the car gets to temperature. I am going to have to check the wiring to the fan from the fuse back to find the issue with it. Shouldn’t take too much work.